Shop Online Now at Northern Tool. This chapter focuses on the hydraulic aspects of design as opposed to structural corrosion safety contamination or instrumentation aspects.

Hydraulic Reservoir Design Considerations

Hydraulic System Design Operation.

. Hydraulic oil spends most of its time in the reservoir and as such various tank design criteria provide benefits for the hydraulic system as a whole. For HFC and HFD fire-resistant fluids the general rule is 5 to 8 times pump flow per minute. When analyzing or designing a hydraulic circuit the following three important considerations must be taken into account.

For open circuits the general rule is a tank oil capacity of 3 to 5 times the flow of the pump s per minute plus a 10 percent air cushion. These ideals are easy enough to achieve on a stationary hydraulic machine in an industrial setting. August 8 2006 Authority.

Station Layout Considerations Provide sufficient work space between pumps Use largest pump and motor dimensions now or future Allow for expansion Think through process of installingremoving pumps and valves Size crane and openings for heaviest largest single item in the station Ensure crane can reach everything it needs to lift. Numerous decisions must be made in designing a storage tank including size location type and expected operation. Section 19-13-B102d2 of the Regulations of Connecticut State Agencies RCSA requires approval from the Department of storage tanks prior to construction.

It seems like there would be a better way of determining the amount of open area. You can imagine a 50-gallon steel box with 150 F liquid inside will radiate a fair amount of heat even if airflow was minimal. Equalization is the primary purpose for constructing water distribution storage tanks.

Photo courtesy of Flodraulic Group. October 20 2014 By Josh Cosford. Never undersize the reservoir.

There are several key considerations in the hydraulic design of water storage tanks. 51006 1 of 10 Water Works Design and Construction Effective Date. Hydraulic power packs are the very heart of your hydraulic circuit so they need to be designed correctly.

The excess reserve oil in a hydraulic system is to dissipate heat and prolong the life of the pump. Here are some important points to consider in designing and using hydraulic systems. Two examples of the special problems faced by designers are machine motion and extreme ambient temperatures.

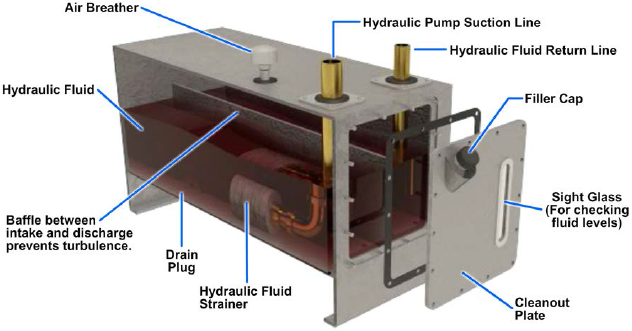

Pressure cap ensures that. Hydraulic power packs come in many different shapes and sizes. Looking for rules of thumb on baffle design for hydraulic tanks.

The location and inlet. Safety of operation 2. To ensure your power pack provides consistent and reliable performance.

Ad Superior Quality Workmanship. In this chapter the word tanks will be used to describe treated water-storage facilities although the term reservoirs is. Allowing for heat dissipation is the main reason to design the tank bottom off the floor.

STORAGE TANK DESIGN AND CONSTRUCTION GUIDELINES rev. This is also why it is important not to stop free airflow around the tank. Ad Find Hydraulic Tanks Reservoirs.

Mobile-hydraulic reservoirs are expected to perform as well as industrial reservoirs even though the mobile variety typically operates under more extreme and often adverse conditions. Reservoirs in industrial applications are spoiled by the extra. From very large and generally stationary industrial units through too much smaller and compact packs designed for mobile applications.

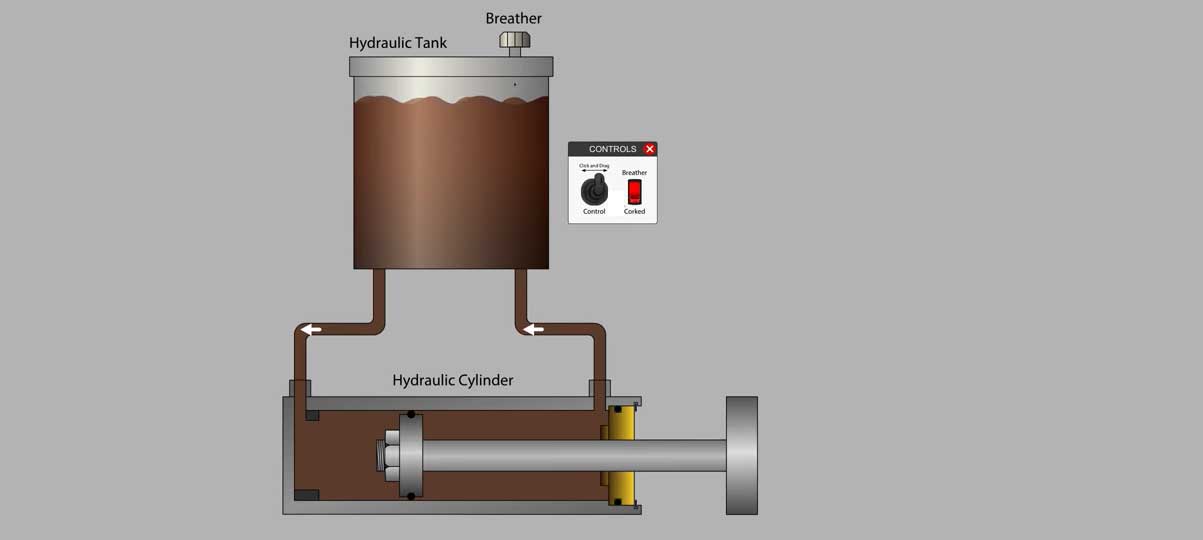

HYDRAULIC CIRCUIT DESIGN AND ANALYSIS A Hydraulic circuit is a group of components such as pumps actuators and control valves so arranged that they will perform a useful task. Company standard which has been around for years states that oil passage cutouts have an area at least 2-12 times the total pump inlet area No one can tell me where this requirement came from. When designing the optimum hydraulic reservoir most of the considerations are in keeping the oil clean and cool.

Ross Offers A Combination Of Engineering And Fabrication Resources. Numerous decisions must be made in the design of a storage tank including size location type and expected operation. Water utilities like to operate treatment plants at a relatively constant rate and wells and pumping stations generally work best when pumped at a steady rate.

There are several key considerations in the hydraulic design of water storage. Over sizing the reservoir by 5 to 15 gallons will offer substantial benefits by allowing the hydraulic system to run cooler and. L-shaped reservoirs have a larger surface area for cooling.

A pressurized or vented reservoir is also to consider when choosing a hydraulic tank. Some Factors to Consider for Hydraulic Tank Drawdown calculations are fundamental. A sufficient amount of fluid must remain in the tank at maximum drawdown.

Cooling considerations The reservoir often just called the tank also provides significant surface area for cooling of the hydraulic fluid.

Fundamentals Of Hydraulic Reservoirs Power Motion

Troubleshooting Hydraulic Reservoirs Breathers And Filters

What Oil Reservoir Size Should I Specify Hydraproducts Hydraulic Systems Hydraulic Power Packs Blog

Hydraulic Tank Design And Work Basic Stuffworking Com

What Is The Function Of A Reservoir In A Hydraulic System Understanding Business Analysis And Engineering Principles

Hydraulic Reservoir Design Considerations

Reservoirs Strainers Filters And Accumulators Engineering Library

0 comments

Post a Comment